Steel

Columbia Business School’s Climate Knowledge Initiative provides business leaders with the curated, actionable knowledge needed to pick investable and scalable green technologies, while unapologetically flagging areas where business and public interests diverge. Here you will find executive briefs, business case studies, PowerPoints, PDFs and more to share, adapt, and use to chart a high-efficiency, low-carbon path.

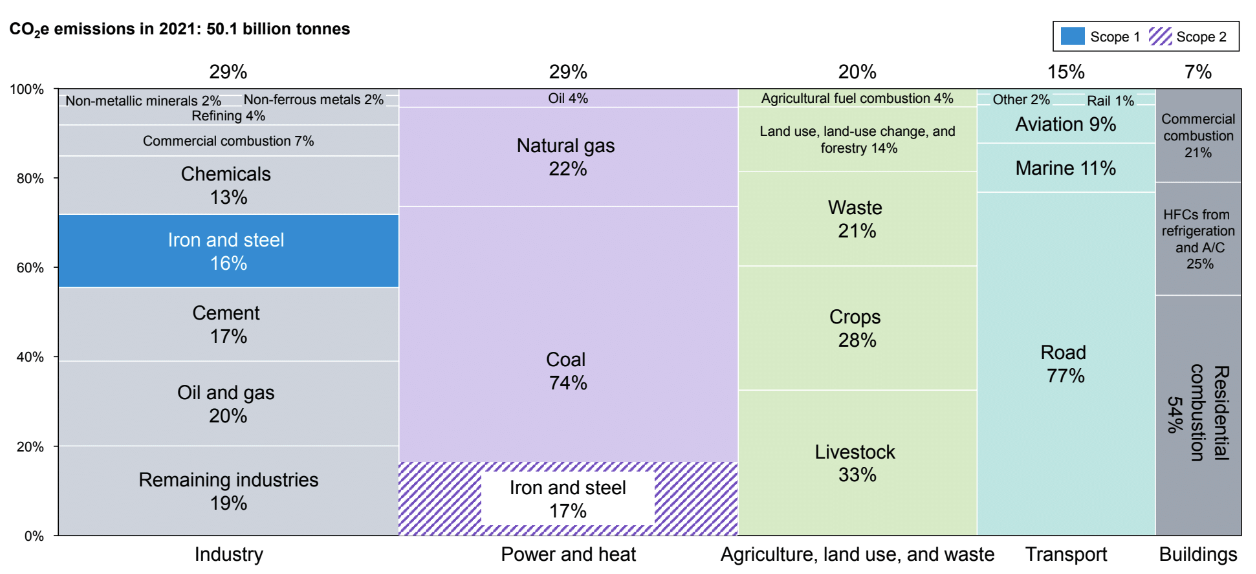

Steel sector scope

Steel sector scope 1 and 2 emissions are ~10% of global emissions

Sources: Scope 1 emissions from Rhodium Group ClimateDeck (September 2023); Scope 2 iron and steel estimate from IEA (2023). Credit: Mimi Khawsam-ang, Max de Boer, Grace Frascati, and Gernot Wagner (22 February 2024); share/adapt with attribution. Contact: [email protected]

Decarbonizing Steel | Resources

Decarbonizing Steel Spotlight

Steel Sector Overview

Global steel emissions have more than doubled since 2000 (from 1.2 gigatonnes in 2000 to 2.5 gigatonnes in 2021).

Steel Decarbonization Technologies

Several emerging deep decarbonization steelmaking technologies now exist: Green hydrogen DRI-EAF, Iron ore electrolysis and Carbon Capture, Utilization and Storage (CCUS).

Steel Sector Trends

IEA expects technology transition to take off after 2030, and CCUS to play the biggest role in 2050 of all green steel technologies.

Cases, Workshops, and Insights

Decarbonizing voestalpine High-Performance Metal

Voestalpine, the Austria-based global leading steel manufacturing division of High Performance Metals, has made a bold commitment. It would achieve climate neutrality by 2050, with chief sustainability officer Philipp Horner leading the charge. Horner and his strategy team must review its entire manufacturing process to find opportunities for decarbonization, including learning about completely new methods for production and reevaluating its existing blast furnace technology.

Electra: Decarbonizing Steelmaking Through Carbon-free Iron

Electra Steel is Sandeep Nijhawan’s brainchild to decarbonize the process of making steel by creating green iron ore.The incumbent steel industry is a big offender when it comes to greenhouse gases, emitting about 2 tonnes of CO2 produced for every tonne of steel, and a major part of emissions-producing steel production hinges on the processing of iron, so Electra’s strategy is to address this part.

Decarbonizing Steel: Four Key Points from Industry Leaders

During a recent workshop at Columbia Business School, experts addressed the challenge of soaring emissions, highlighting the urgent need for a comprehensive transformation across the industry.